Located in Katsuyama, this factory sits on the border of Ishikawa prefecture in northeast Fukui. Situated near Mount Haku, the Katsuyama Factory got its start during the Taisho era, and since the beginning, it has used the abundant hydro-power of the Kuzuryu River to melt metals for our products.

During our long history, we have faced many management crises, but our predecessors' knowledge and unfailing efforts kept the melting furnaces burning throughout the years, allowing us to improve technologies and keep our passion burning down to this day.

We are still fueled by the same enthusiasm, and continue ever forward in our home at Katsuyama.

| Type | Name | Quantity |

|---|---|---|

| Melting | High-frequency induction furnace | 9 |

| Machining | Crushing line | 14 |

| Packaging | Automated packaging line | 8 |

| Cored Wire manufacturing | Cored Wire formation line | 4 |

| Testing and inspection equipment | Scanning Electron Microscope(SEM) | 1 |

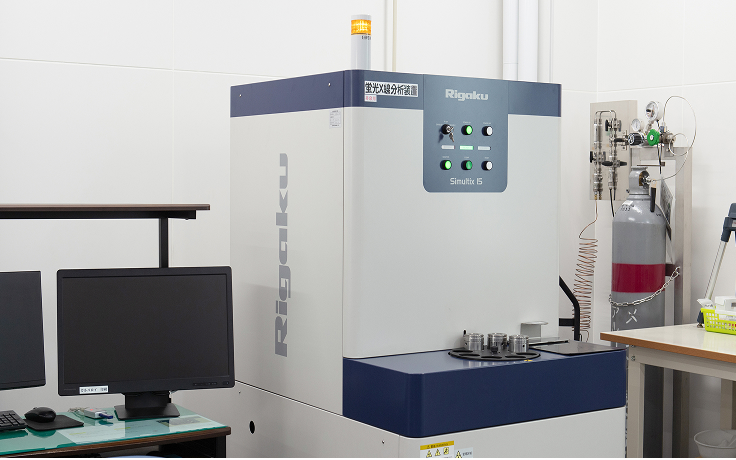

| Testing and inspection equipment | X-ray Fluorescence Spectrometer | 1 |

| Testing and inspection equipment | Energy Dispersive X-ray Fluorescence Spectrometer | 2 |

| Testing and inspection equipment | Oxygen-Nitrogen Gas Analyzer | 1 |

| Testing and inspection equipment | Carbon-Sulfur Analyzer | 1 |

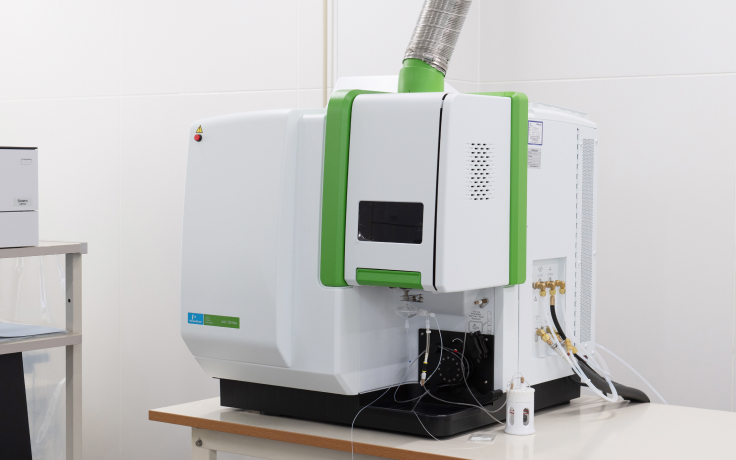

| Testing and inspection equipment | ICP-OES Analyzer | 2 |

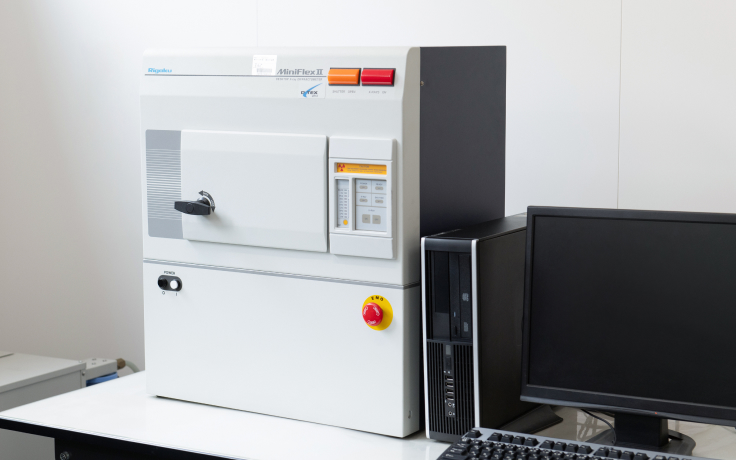

| Testing and inspection equipment | Powder X-ray Diffractometer | 1 |

| Testing and inspection equipment | Brinell Hardness Tester | 1 |

| Testing and inspection equipment | Universal Testing Machine | 1 |

| Testing and inspection equipment | Automated Sample Pre-Processor | 2 |

| Testing and inspection equipment | Optical Microscope | 1 |

| Testing and inspection equipment | Digital Microscope | 1 |

| Warehousing | Category II hazardous material storage & hazardous material factory | 1 |

We offer superb quality assurance with a production management framework, cutting-edge testing equipment in each process ensuring the most rigorous inspections, and an ISO quality management system.

The Katsuyama Factory obtained ISO 9001 (Quality Management System) certification in 2005 and ISO 14001 (Environmental Management System) certification in 2006. Based on these systems, we engage in high-level management in both quality and environmental areas, allowing us to contribute to achieving a sustainable society through safe, reliable product manufacturing.

JQA-EM5509

Katsuyama Factory

Takashima Factory

JQA-QMA11953

Katsuyama Factory

Takashima Factory

Osaka Factory

In manufacturing special alloys, which use a large volume of rare metals, we look to China, which owns nearly 60% of the world's mineral resources, and operate a factory in Liyang, Jiangsu. Combining OTG's proprietary alloy melting technology with China's abundant mineral resources allows us to provide a stable supply of high-quality special alloys and contribute to business continuity plans (BCP).

INONIBRAS S/A was established as our wholly-owned company in Brazil in 1973 for the production of high-quality ferrosilicon. Although we transferred the company's shares to RIMA S/A in Brazil in 2022, we have maintained a partnership with them, engaging in employee interchanges and factory audits, enabling stable procurement of high-quality ferrosilicon.

The production of ferrosilicon, the main raw material for special alloys, consumes significant electricity, and tends to release large amounts of carbon dioxide when burning coal-derived cokes. To avoid such environmentally damaging processes, we actively procure ferrosilicon that is produced in Brazil using hydroelectric power and eucalyptus-derived biomass material (charcoal).

In fiscal year 2024 at the Katsuyama Factory, we succeeded in reducing melting power units by 3.1%, greatly contributing to energy savings and receiving a Class A rank in the SABC evaluation system based on the Japan Act on the Rational Use of Energy. Averaged over the next five years, we aim to continue cutting annual power usage by at least 1%, and achieve a Class S rank.